R.A.N.D. MUZIK PRESENTS

MACHINES THAT HIT THE SWEET SPOT.

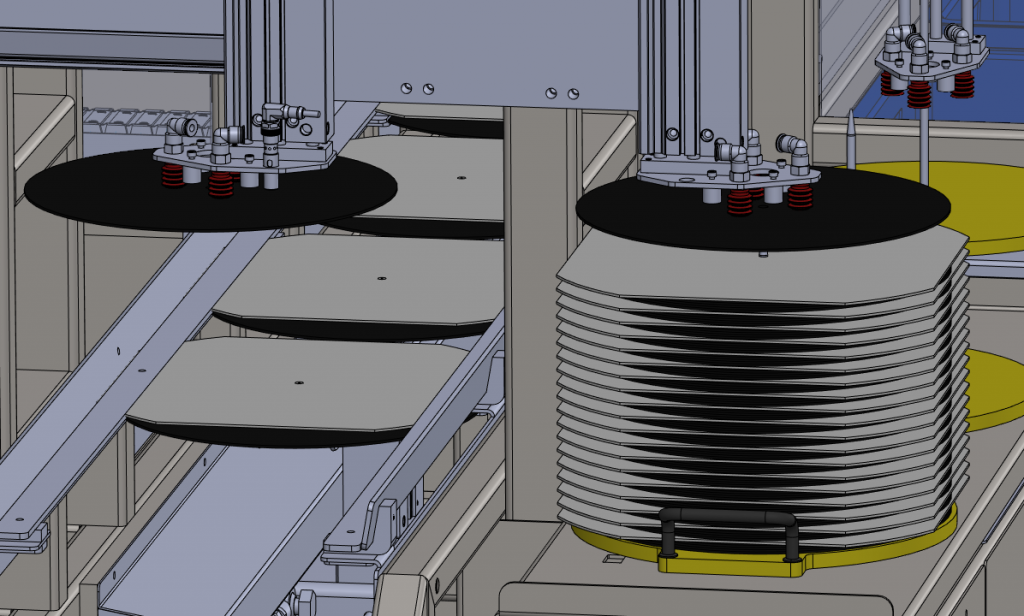

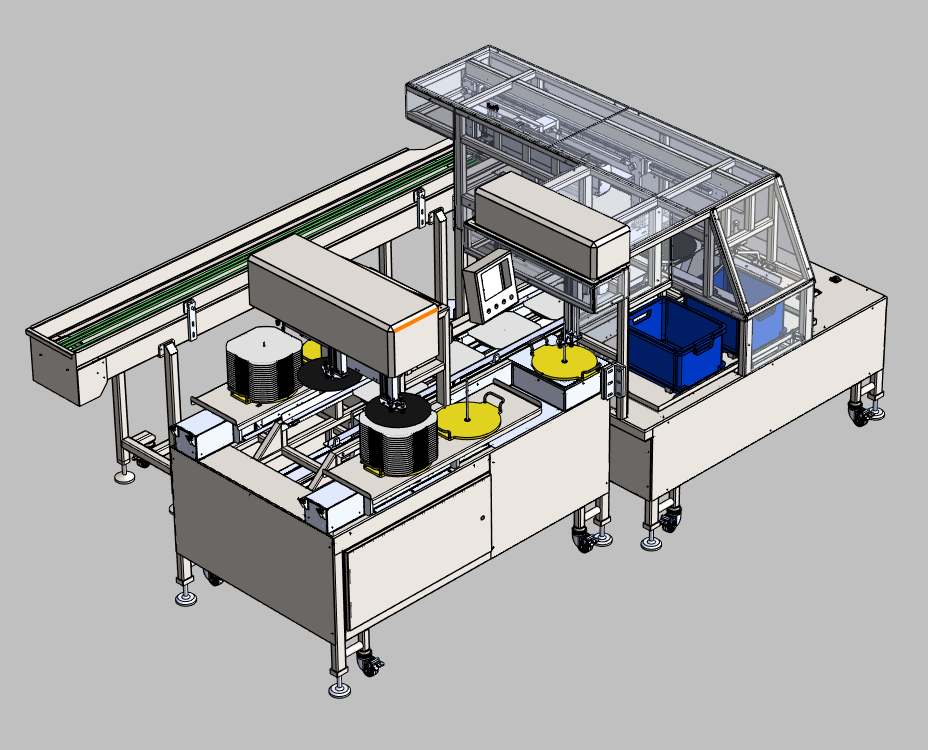

12" Record Servo Sleever

Our fast packer

Quick sleeving of records into paper sleeves

Key Facts:

▪ up to 1200 an hour

▪ world's first servo driven record sleever with 4 liniear motion axis

▪ 4 servo-motors for a smooth running

▪ extended record and sleeve magazine

▪ extended record and sleeve magazine

▪ dimensions (LxWxH): 3700 x 2350 x 1750 mm

▪ available soon

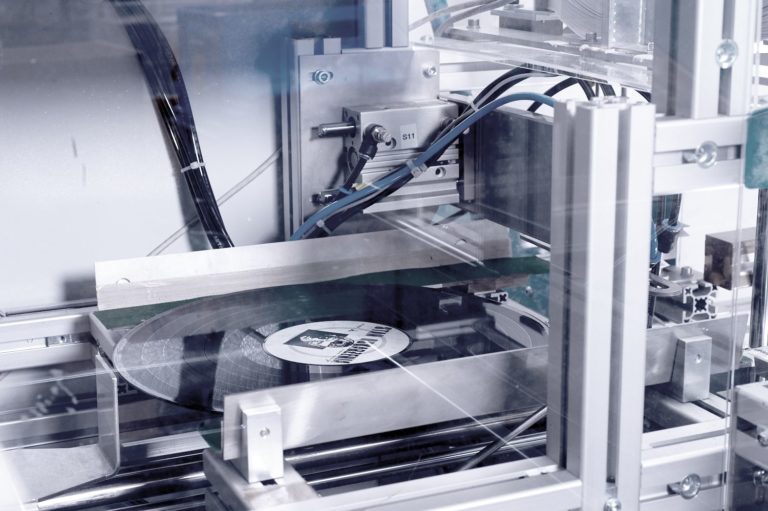

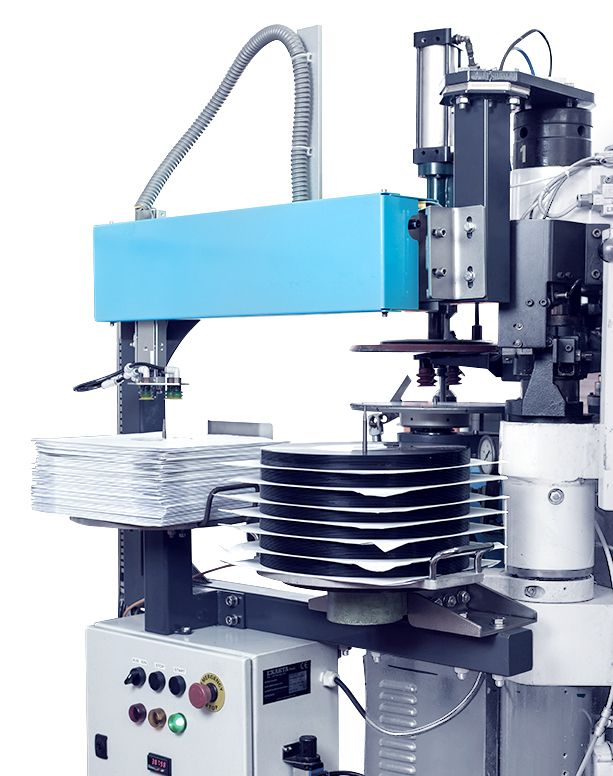

12" Record Sleeving Machine

Our Compact Packer

Compact sleeving of records into paper sleeves

Key Facts:

▪ up to 800 an hour

▪ record size 12 inch

▪ sleeve size (LxW) 307 x 310 mm

▪ packing speed: 10-15 sleeved records

▪ dimensions (LxWxH): 1680 x 1640 x 2150 mm

▪ weight: 350 kg

▪ compressed air connection: 0.6 m³/min @ 6 bar; dry compressed air required

▪ operating voltage: 115V or 230V / 1 KW

▪ multi-machine operation possible

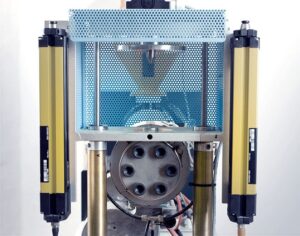

Matrix Separator

Does the Separating that needs to be done

The matrix separator is the perfect tool for cleanly removing new electroformed matrices from their template shells. Original foils, "negatives" and the records themselves are separated quickly, cleanly and with precision.

Key Facts:

- components: hub cylinder, suction regulator, separating blade and a vacuum valve all mounted to the base plate.

- a pneumatic foot pedal controls the closing and opening of the separator.

- various models available: delivery with or without a vacuum pump

- connection to a central vacuum supply (0.6-0.9 atu) is required for separators not

equipped with a vacuum pump.

- for machines equipped with a vacuum pump:

- drive power: 0.08 KW

- operational voltage: 220V/50Hz

- connected load value: 1 A

- air pressure: 5-8 bar

Spindle Cart with Stacking Spindles

Organizational Genius

A custom-sized cart with stacking spindles making sure that your production space is used to the fullest while serving as a carrier for your records.

Key Facts:

- maximum capacity per stacking spindle: 100x12"

- maximum capacity per cart: 6 stacking spindles

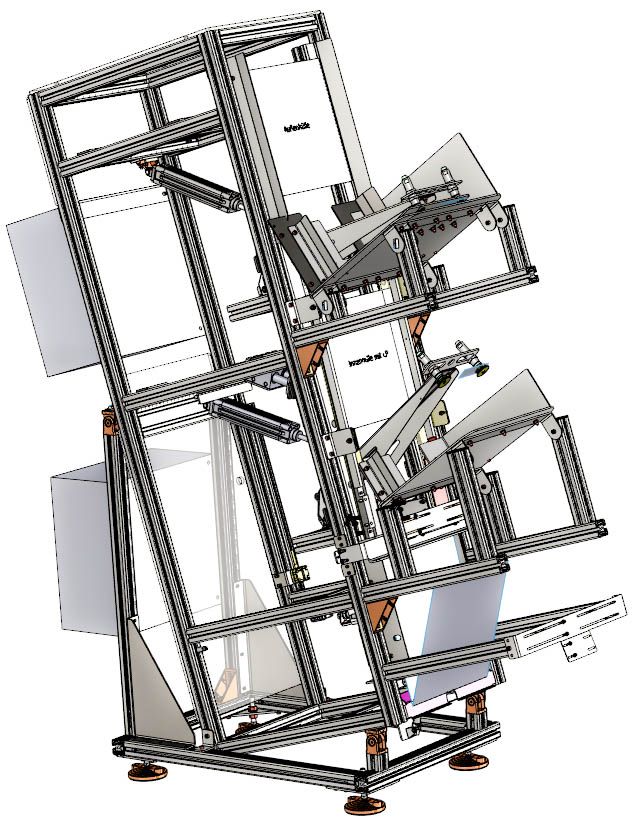

The Cooling Plate Seperator For Toolex AD12

Real Quick. Real Safe.

The precision instrument for your production line. This automated machine ensures effective, individual separation and transport of cooling plates during the pressing process. And it even includes a counter.

Key Facts:

- magazine with a 50 cooling plate capacity

- warning mechanism for minimum or maximum fill level exceedance

- freely adjustable number of records per cooling pate

- easily readable preset batch counter on the front

- operational connections: compressed air (6 bar)

- operational voltage: 15 or 230 V

Extruder P50U For Hand-Operrated Record Presses

Our Patty Cake Specialist

Ensures the consistent, precise quality of your record moulding material. The extruder can be used with any manual, hand-operated record press and provides automated processes for the formation of the vinyl "patty" mass.

Key Facts:

- single-screw extruder

- driving power 5.5 kW

- material throughput 180g /10 seconds

- electr. connection: 380V/50Hz 16A

- compressed air: 3-6 bar

- cooling water if necessary: 2-4 bar

- weight: 280 kg

Motorized Cutter

For the Workbench

For precision outer edge shearing of nickle masters.

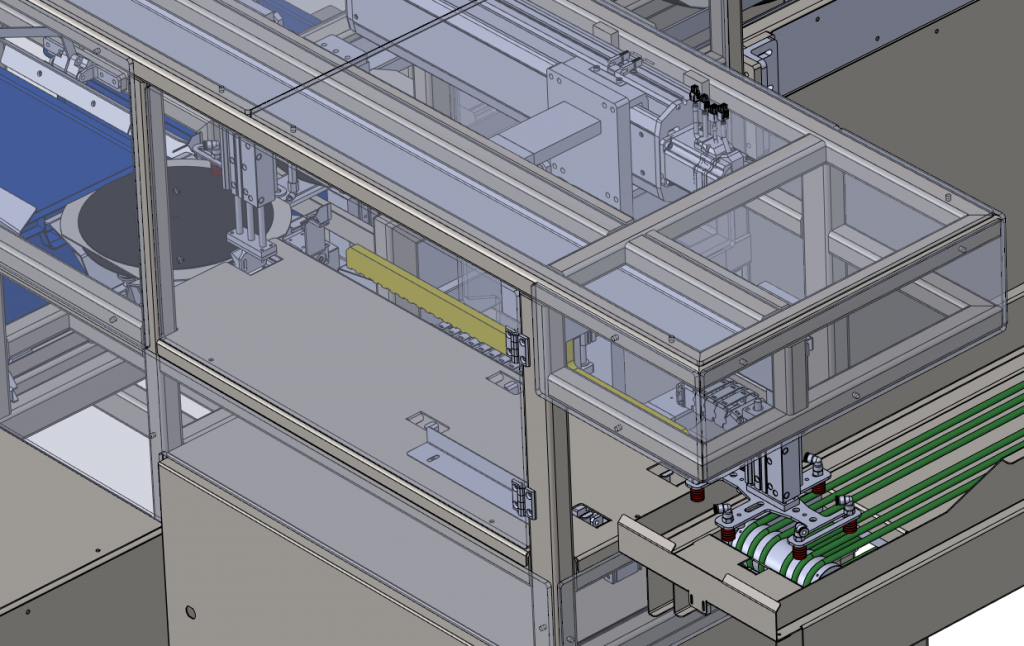

12" Cover Packaging Machine

Speed Up!

Non-stop packing of sleeved records into hard covers - up to 900 an hour.

Place Your Request

We are glad to see that you recognize quality. Do you have a service request, order or other type of inquiry for us?

We are looking forward to hearing from you.

ABOUT US

R.A.N.D. Muzik - The Newest and Best in Record Production

We at R.A.N.D. Muzik have been working for more than 15 years on improving the manufacturing and production processes involved in record making. As trained mechanical engineers, we have turned our love for music´s black gold, traditional processes and modern components into a special kind of expertise which we would like to make available to you in the form of our machines and services.

In the past, if you wanted to start producing your own vinyl records, the only option available to you was to take over or reactivate old and worn down production lines. Now you are able to get technologically modernized components which we have developed in our own production facilities and thoroughly tested under real world conditions.

Our portfolio covers a variety of different devices and equipment for both electroplating and press technologies as well as quality control.